Gas treatment systems

The equipment manufactured by our company is used conditioning of any gas type: natural, associated petroleum, mine, shale, biogas, etc.

By virtue of the fact that each gas type has its own physicochemical properties, the original gas shall be conditioned variously at different stages taking into account the gas type, composition and purpose.

The booster compressor stations (BCS) and gas conditioning facilities (GCF) are used:

- in oil and gas industry;

- in power industry;

- in oil and gas chemistry.

It is required to clean any gas of mechanical impurities, monitor flow rate, increase or reduce pressure in compliance with the end user’s requirements. For this purpose it is required the gas conditioning equipment manufactured and supplied by our company.

We implement projects of any complexity from the gas pipeline tie-in point to the end user, including all necessary equipment:

- high alert automatic gas distribution stations ready-to-use;

- gas conditioning facilities;

- commercial and process-oriented gas metering units;

- gas reduction units;

- booster compressor stations;

- closed cooling systems;

- gas heaters;

- emergency and stop valve units.

Our products:

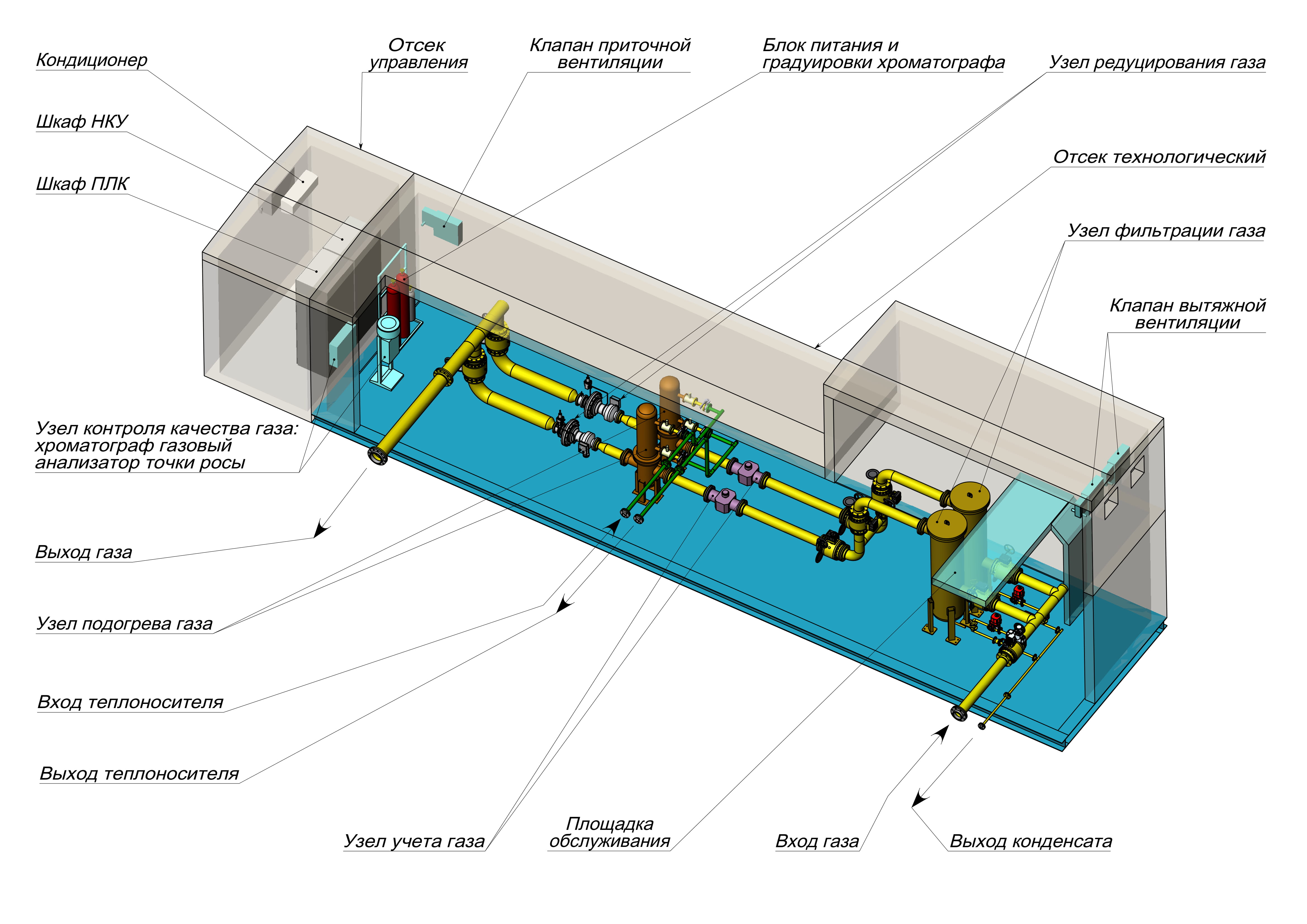

1. Gas conditioning facilities

Use:

The packaged multifunctional facilities are designed for gas pre-conditioning before its supply into the gas equipment, including gas turbines, gas powered electrical generators, compressor stations, boiler houses, gas compressor units.

Purpose:

- intake of breakaway release of liquid;

- gas filtration of mechanical impurities and liquids;

- gas reduction and heating;

- ripple smoothing of the gas mixture;

- commercial or process-oriented gas metering.

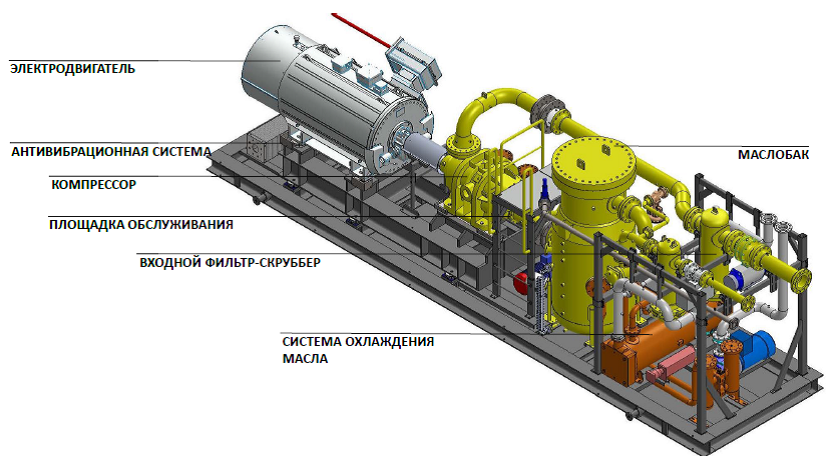

2. Booster compressor stations

The booster compressor stations are widely used both in power industry and in the oil & gas industry:

Use:

- large thermal power plants;

- small power facilities;

- stand-alone power supply centers for industrial enterprises;

- gas turbine tables;

- for gas collection for further transport of gas in the pipeline;

- conditioning of APG as a fuel for the BOP power centers based on gas-turbine thermal power plants or combined cycle gas turbine power plants on the deposits;

- APG flood to increase crude oil production.

In compliance with the customer’s requirements, we can select the optimum type of compressor unit, complete the gas conditioning facility, taking into account the operational features.